Vitas

Since 1965, VITAS has produced Gate, Globe and Check valves in accordance with the most important international standards in the Oil & Gas and Power sector.

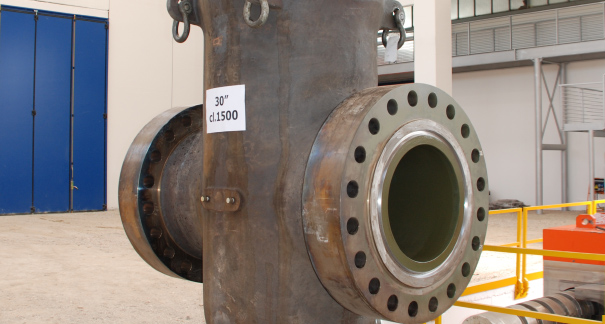

The production covers a wide range of valves in terms of sizes, from 1/2” to 72", and materials: carbon steel, alloy steels for low temperature, stainless steels, duplex, superduplex, inconel and titanium.

VITAS is able to design and produce valves of the very highest quality and dedicated design at the request of the client, meeting all the technical requirements, including specific design for various applications.

The factory, located in Brendola (VI), extends over 29,000 m2, of which 15,000 m2 are under cover, with a production capacity of 2,000 valves a month. It can handle assembled valves of weights of more than 80t and over 15 metres in height. It has 10 machine tools for mechanical processing of components weighing up to 40t, as well as lapping machines for processing spheres with diameters up to 60". The 12 hydraulic and pneumatic test benches have capacities between 0.5” and 60”. The factory is equipped with an outside bunker with remote control console for special tests, such as gas, high pressure, cryogenic, high temperature, submersion in liquid, cyclical functional tests and fugitive emissions tests.

At the request of the client, standard VITAS products can also be produced in our factory in China.